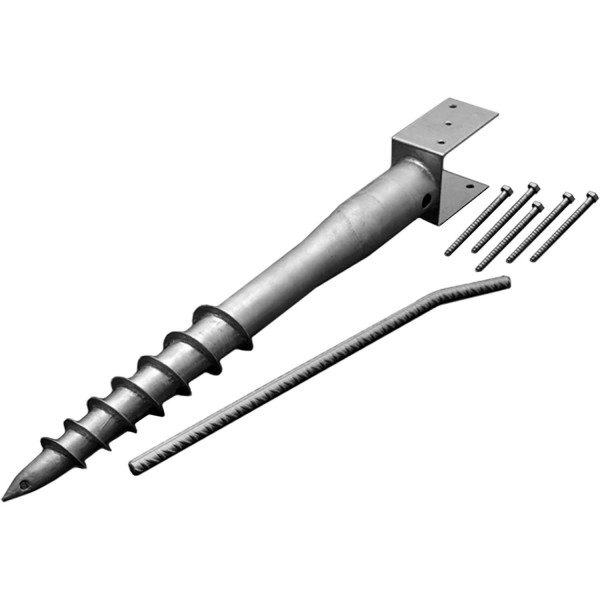

Solar Panel Mounting Washers Description

Solar panel mounting washers are essential components for mechanical stability and structural integrity of solar mounting systems. They evenly distribute loads, reduce stress concentration, and prevent long-term damage in residential and commercial solar installations.

These washers are also widely used in industries such as automotive, medical, marine, and industrial equipment, where load distribution and vibration resistance are critical. When selecting solar washers, consider material, hole diameter, thickness, and surface treatment for optimal strength and corrosion resistance.

Get a Quote

Features of Solar Panel Mounting Washers

- Flat and Smooth Surface: Precision-crafted, burr-free surface for tight and reliable fastening without damaging panels.

- High Strength and Load Bearing: Withstands high tensile and compressive forces, maintaining stable support over time.

- Standardized Hole Sizes: Consistent specifications for precise alignment and easy installation.

- Wide Range of Sizes: M3, M4, M5, M6, M8, M10, and custom sizes to suit various mounting systems.

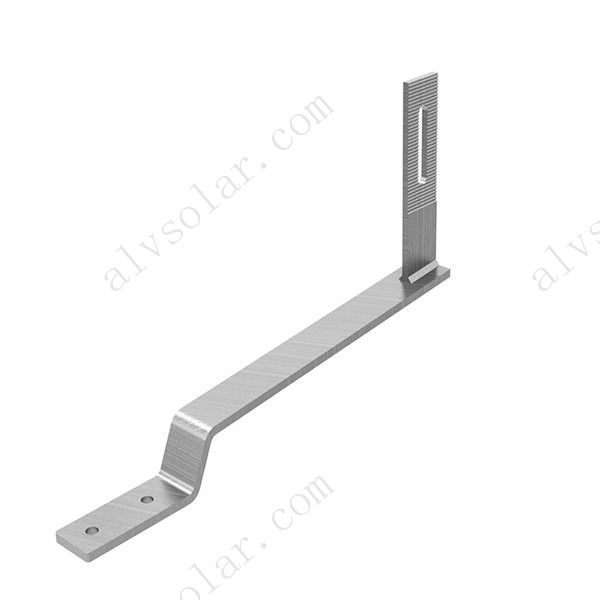

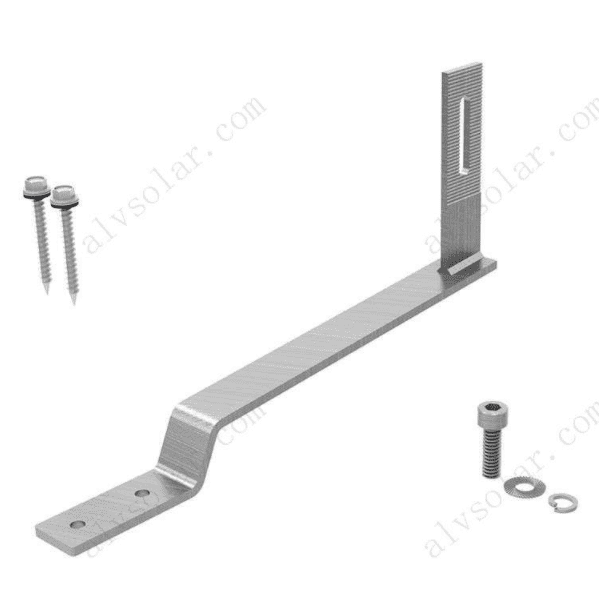

Flat Washers for Solar Panel Mounting

Flat washers evenly distribute fastener loads and prevent surface damage. Ideal for solar racking, panel mounting, and industrial applications. Made from high-grade stainless steel with optional carbon steel or nylon, available in M3–M10 and customizable finishes (zinc plating, galvanization, colored coatings).

Solar Panel Mounting Washers Specifications

| Washer Type |

Common Sizes |

Material |

Surface Treatment |

Application |

| Flat Washer |

M3, M4, M5, M6, M8, M10 |

Stainless Steel, Carbon Steel, Nylon |

Plain, Zinc-Plated, Galvanized, Custom Colors |

Solar Mounting, Industrial Fastening, Automotive |

| Spring Washer |

M3, M4, M5, M6 |

Stainless Steel, Carbon Steel |

Plain, Zinc-Plated |

Vibration-Resistant Mounting Applications |

| Serrated Lock Washer |

M3, M4, M5, M6 |

SS 304/316, Carbon Steel, Alloy Steel, Brass |

HDG, PTFE Coating, Plain, Galvanized |

Dynamic Load and Locking Systems |

Spring Washers for Solar Systems

Spring washers (split lock washers) resist loosening from vibration or dynamic loads. Their helical shape generates tension and friction to maintain tight connections. Suitable for wood, metal, and composite materials.

Serrated Lock Washers

Serrated lock washers provide superior anti-loosening performance even without high initial preload. Radial serrations grip surfaces, ideal for systems with vibration or movement. Available in stainless steel, alloy steel, and brass with protective coatings.

Why Choose ALV as Your Solar Mounting Washer Supplier?

- Customized Solutions: Full customization of materials, sizes, coatings, and packaging for solar PV projects.

- Eco-Friendly Manufacturing: Green production practices with recyclable materials for sustainable solar systems.

- Reliable Supply Chain: Strict quality control and fast delivery for consistent performance and timely support.

Solar Panel Mounting Washer FAQ

What types of washers do you offer?

Flat washers, spring washers, serrated lock washers, sealing washers, and custom-designed options.

Which materials are available?

Stainless steel (304, 316), carbon steel, brass, nylon, and specialty alloys.

Do you offer surface finishes?

Yes: plain, galvanized, zinc-plated, black oxide, PTFE-coated finishes.

Minimum order quantity?

Varies by washer type and size. Contact our sales team for a quote.

Technical data available?

Yes, drawings, dimensional charts, and performance data sheets are available upon request.

Quality control?

Full inspection protocols and lab testing to meet international quality standards.

Additional Information

Role of washers in a solar mounting system

Distribute load, prevent fastener loosening, absorb vibrations, and provide insulation against galvanic corrosion.

Why is 304 stainless steel sometimes magnetic?

Generally non-magnetic, but cold working or manufacturing-induced phase changes may cause slight magnetism.

Common types of stainless steel:

- Austenitic: 304, 316 – excellent corrosion resistance.

- Ferritic: 430, 446 – magnetic with moderate corrosion resistance.

- Martensitic: 410, 420 – high strength and wear resistance.

- Duplex: 2205, 2507 – combines corrosion resistance and strength.

- Precipitation Hardening: 17-4PH, 15-5PH – heat-treatable high-strength grades.

How to choose the right washer size?

Match the washer’s inner diameter to the bolt or screw outer diameter for optimal load distribution and secure fastening.

Can washers be reused?

Flat washers may be reused if undamaged; spring or serrated lock washers should be replaced after use.

Contact Us

For pricing, samples, or custom specifications, submit an inquiry or reach out to our sales team.